Trusted Long-Term Potable Water Protection

When it comes to long-term performance in exposed liner and cover applications, HypaFlex® (Chlorosulfonated Polyethylene – CSPE) is the gold standard. Engineered to withstand extreme heat and UV exposure, HypaFlex® has been used extensively for water containment and protection for over 50 years and is backed with an industry-leading 30-year weathering warranty.

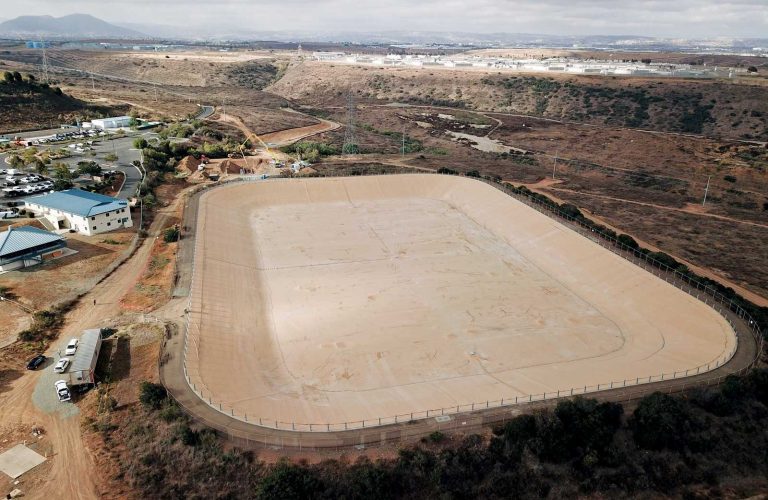

The use of HypaFlex® floating covers in reservoirs is one of the most economical methods of storing and treating large volumes of water. Reservoirs using CSPE are often up to 70% more cost-effective versus above-ground tanks or underground clearwells. With over 400 successful floating cover projects worldwide, you can trust that HypaFlex® is built to last.

Why Choose HypaFlex®?

Excellent UV Resistance

The saturated, stable polymer backbone structure provides excellent longevity and UV resistance, ideal for long-term exposed applications.

Enhanced Flexibility without Additives

Does not require the use of volatile materials such as liquid plasticizers, process oils, or stabilizers used to achieve a high degree of flexibility.

Additional Features

- NSF Certified for contact with potable water

- Exceptional longevity and UV resistance

- Up to 30-year weathering warranty

- Available in several styles, colors, and thicknesses

- Highly resistant to ozone, oils, and other chemicals

Product Details

HypaFlex® is a premium reinforced flexible geomembrane material with excellent longevity and UV resistance, engineered for long-term applications, including floating covers and exposed liners.

Downloads

Product Specifications

Resources

Explore the resources available to help you acquire additional knowledge on our products. If you cannot find what you are looking for, we are here to help.

Case Studies

Discover a wide range of completed Layfield projects in various applications worldwide.

Webinars

Our Technical Services Team continuously creates and presents webinars and lunch presentations to better educate our clients. We would be happy to provide you and your group with a customized presentation based on your specific needs. We are also pleased to provide a series of pre-recorded webinars curated for this product group and shown below.