Safe, Secure, & Sustainable Fluid Solutions.

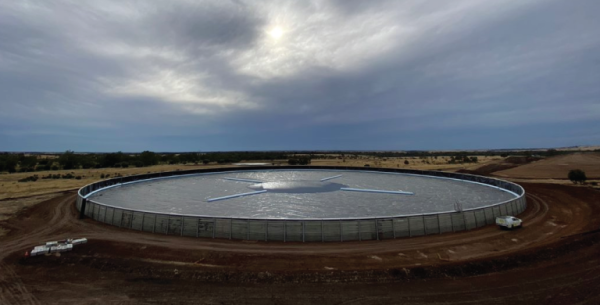

The Concept Tank™ is the world’s largest relocatable water storage tank. Ranging in size from 16,000 m3 (100,000 Barrels) to 80,000 m3 (500,000 Barrels), the modular, precast concrete panel tank is quick to install, requires no concrete foundations, and can be relocated and resized as required.

With multiple containment layers and monitoring systems, the Concept Tank™ offers the highest standard of fluid storage on a mega scale.

Offering up to a 25-year design life, the relocatable Concept Tanks™ are constructed for various applications, including:

- Produced water storage

- Potable water storage

- Process Effluent

- Freshwater Storage

- Mine Water

- Leachate

CONCEPT Tank™ Sizes

CAPACITY | Diameter

• 16,000 m3 (100,000 Barrels) — 270 feet

• 32,000 m3 (200,000 Barrels) — 375 feet

• 48,000 m3 (300,000 Barrels) — 450 feet

• 65,000 m3 (400,000 Barrels) — 510 feet

• 80,000 m3 (500,000 Barrels) — 560 feet

What are the benefits to the Concept Tank™ Solution?

Our innovative solution provides greater benefits compared to traditional storage methods.

Safe

Concept Tanks adheres to the strictest safety protocols during every stage of construction. All tanks are well engineered and lined using NSF 61 certified Enviro Liner® geomembranes.

Sustainable

Concept Tanks™ offer a superior solution over traditional fluid storage methods by significantly reducing the environmental impact on the immediate and surrounding area.

Fast Installation

Due to its unique, modular design, Concept Tanks™ have rapid installation times, giving greater flexibility to project timelines.

Case study

4MG Concept Tank™ – Refinery Process Liquids

This case study describes a challenge at a site where valuable process fluid was being lost to a tailings dam during shutdowns, causing revenue loss and environmental concerns. The client initially considered constructing a lined earthen pond but dismissed it due to cost and environmental issues. The solution involved prefabricating two Concept Tanks off-site, reducing permitting time, and enhancing leak detection and containment monitoring. The tanks were quickly installed, minimizing disruptions and improving safety, and are now being expanded to alleviate further pressure on the tailings storage facility.

Case study

3MG Concept Tank™ – Dust Suppression

Concept Tanks was engaged by a client to develop a solution to complex dust suppression requirements in remote Western Australia. This Pilbara-based project saw our in-house design team solve various environmental concerns through an innovative Concept Tank™ and cover design. The walls of the 3 Million Gallon Concept Tank™ were raised to keep local fauna out, and the tank was equipped with a satellite leak detection system to keep operators informed remotely. A floating cover was also designed and installed to protect from seed and dust contamination.

The project took 2 months to complete, leading to significant cost savings for Monadelphous while remaining environmentally friendly.

Case study

352K Barrel Concept Tank™ – fluid storage

A client engaged Concept Tanks to assist with fluid storage for its operation in Australia, producing natural gas for domestic supply. The complex natural gas project required an immense 30 Million Gallon brine storage solution, which Concept Tanks was able to deliver quickly and efficiently.

The Concept Tank™ solution involved deploying two 15 Million Gallon modular concrete tanks in just two months. The Concept Tank™ system was designed with various safeguards for the harsh conditions of the region. The double-liner featured water tube ballasting to ensure liner integrity at any water level; a must when dealing with evaporation in extreme climates. Radar level sensors are monitored remotely, and a sealed poly sump provides added durability compared with conventional options.

Contact Us Today To Learn More About Concept Tanks.

"*" indicates required fields