May 2025 | Layfield Geosynthetics

Raising the Bar for Geonet Innovation and Performance: Fortifying the weak link in a double lined system. It’s what’s in the middle that counts!

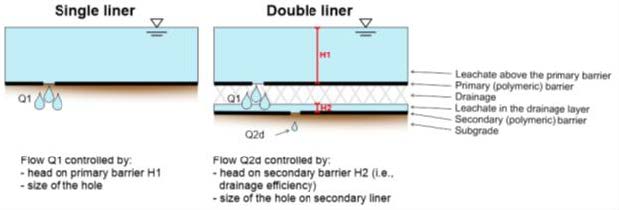

The geosynthetic community has improved geomembrane liners immensely over the last several years. We can now expect a well-designed geomembrane to last for hundreds of years at the bottom of a municipal solid waste landfill. In most cases, the liner system consists of two geomembrane layers and a drainage layer in the middle. The problem is, what’s between the liners is being built to a lesser standard. To paraphrase an old saying, a system is only as strong as its weakest link – why are we not paying more attention to the weak link?

Geonets used in a drainage layer between the primary and secondary liner provide two critical functions, one is to drain any leachate that has penetrated the primary liner to a sump. The second is to reduce the driving head of a leak in the secondary liner by providing a positive outlet. Both functions are necessary and required for the entire life of the containment system. This is illustrated in Figure 1 below.

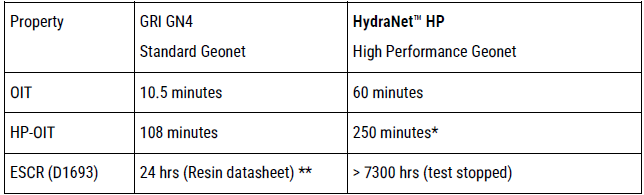

A typical geonet pales in comparison to a well-designed modern geomembrane in terms of longevity properties. Oxidative Induction Time (OIT) and Environmental Stress Crack Resistance (ESCR) are two properties that are widely accepted as longevity indicators for a geosynthetic. In the case of a typical HDPE geomembrane, the minimum requirements for OIT and SCR are 100 minutes and 500 hours, respectively. For an industry-standard GRI-GN4 geonet, the OIT is about 10 minutes, and the SCR is less than an hour, substantially lower values that are indicators of a much lower life expectancy when subject to the stressors normally seen in a containment system.

Industry thought leaders have been asking for better.

Layfield responded by developing a high performance geonet made in our Edmonton, Alberta, Canada facility. It was developed specifically for a demanding containment project at a mine site, then we decided to make it available for all our customers. It combines improved antioxidant properties and enhanced stress crack resistance to closer match the other layers of the containment system. Additionally, it is made with a next generation bi-modal resin, well known to enhance the longevity of polyethylene. At its core, bi-modal technology allows polyethylene to hold on to its antioxidants longer than standard uni-modals (standard HDPE). Moreover, the presence of both long and short molecular chains significantly increases the properties like stress crack resistance, despite their higher density. More on bi-modal resins here.

In summary, when designing a containment system, we believe it is prudent to examine each component for long term performance and ensure the layers match up. A system is only as strong as its weakest link. We believe our Innovative HydraNet™ HP series of geonets and geocomposites have taken a step in the right direction. We encourage you to consider our innovative series of geonets and geomembranes for your next containment system to help ensure long life and durability of your critical containment project.

Related Articles

View All News