Written by Chelsea Bolton, Engineering Business Manager

PROJECT SUMMARY

The North Shore at Mandalay Bay Soil Remediation Project in Oxnard, California, is part of an ongoing major land redevelopment effort converting a former oilfield waste disposal site into a residential housing community. The project scope centers on the design and development of an on-site treatment containment cell using high-performance geomembranes for the remediation of

unforeseen contaminated soils impacted by trichloroethylene (TCE), perchloroethylene (PCE), hydrocarbons, and other fuel and oil-related compounds. Rather than removing the impacted soils for off-site disposal, the design team elected to treat the material onsite, allowing the clean soils to be reused in future construction activities. The project promotes environmental sustainability by reducing export emissions, haul-off and disposal costs, and supports environmental recovery.

SOLUTION

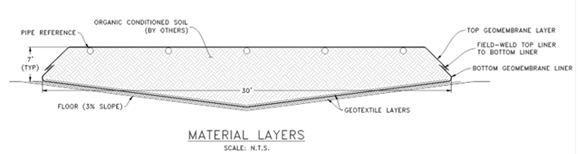

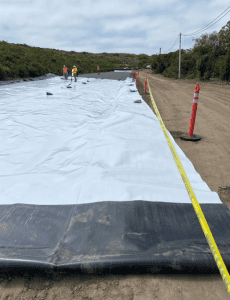

Layfield worked with the Engineer to develop a geomembrane-lined treatment cell to support onsite anaerobic bioremediation of impacted soils. The project quickly transitioned to the construction phase, during which Layfield was contracted to supply and install the geomembrane. Contaminated soils were placed within a fortified blended geomembrane containment system manufactured to provide chemical resistance, flexibility, and durability for long-term, UV-exposed applications.

The remediation strategy involved the addition of iron and organics to facilitate the anaerobic breakdown of the chlorinated solvents found in the soils. To maintain the required moisture levels while preserving an airtight environment, a custom irrigation drip line system was installed in the treatment cell. Inspection ports for soil sampling were required; Layfield was able to prefabricate 50’ x 330’ panels to include pipe penetrations every 10’. Capped PVC pipes were placed in designated areas, and Layfield’s pipe boot kits allow for extrusion welds to the liner cap.

The material selected for both the base and cap was Enviro Liner® 6040, a specialty geomembrane that uses a blend of LLDPE/HDPE resins and other additives, including UV stabilization, giving the material excellent strength, flexibility, durability, and strong chemical and UV resistance.

Once the base liner was in place, the contaminated soils were placed over top of the geomembrane, and the stockpile was subsequently capped with another layer of Enviro Liner® 6040 that was welded to the base liner. Wedge welding was used at prefabricated panel seams, while extrusion welding secured the base and cap liners to create an airtight sealed treatment cell. Both liners were installed with the white side of the material facing up to minimize heat buildup, reduce thermal expansion and contraction of the geomembrane, and mitigate the potential for gas-related deformation beneath the liner.

CHALLENGES & RESULTS

The project presented several unique challenges, including the risk of chemical exposure fromchlorinated solvents, limited workspace for welding and installation, a steep 1:1 slope, and the need for a containment system capable of high-performance during a multi-year treatment period. Moisture control and gas management were also critical to ensuring effective anaerobic remediation.

These challenges were addressed through careful material selection, Layfield’s expertise in design assistance, and an experienced field crew for project execution. Enviro Liner® 6040, a fortified polyolefin alloy geomembrane with an advanced UV and antioxidant package, provides excellent chemical resistance, flexibility, and durability. The fully installed system successfully established a controlled treatment environment, allowing soils to eventually be reused onsite. This solution supported regulatory compliance, environmental protection, and sustainable land reuse while advancing the overall redevelopment of the property.