Project Summary

An engineering firm designing a new copper and nickel mine in Ontario approached Layfield for assistance in selecting an appropriate geomembrane lining system to provide a continuous barrier beneath the waste rock storage area. The geomembrane would need to withstand the load and stresses induced by a large waste rock pile at the site located in Northern Ontario for a 15-year design life. The waste rock from the copper and nickel mine was expected to be acid generating with a very low PH and pose a significant risk to the surrounding environment.

Solution

The engineering firm worked closely with Layfield’s technical resource team to explore several geomembrane options, including HDPE, LLDPE and specialty geomembranes manufactured by Layfield.

To assess chemical compatibility with the lining materials against this unknown mine leachate, Layfield provided an immersion kit to the client containing small samples of various geomembrane liners, including HDPE, PVC Alloy, and Enviro Liner®. The client immersed geomembrane samples with a leachate sample from an adjacent mine site with similar leachate properties for a 30-day period.

Following the immersion period, the client returned the geomembrane samples to Layfield’s lab to compare the physical properties, including mass, tensile, elongation and thickness, before and after immersion and examined the geomembrane samples for signs of chemical degradation. Chemical degradation typically begins at the material’s surface, where the chemical reacts with the polymer and oxidizes the surface. This process breaks the molecular chains and polymer core, weakening the geomembrane.

From the samples provided, Enviro Liner® EL6000 was recommended for the application. The sample exhibited no chemical degradation or weakening of the tensile properties.

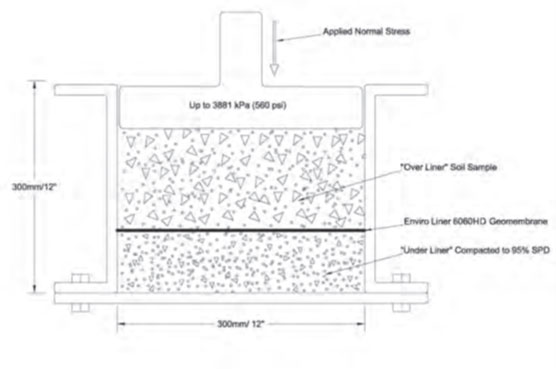

Another concern raised by the engineer was the geomembrane’s ability to withstand the forces and compressive load of the waste rock pile above.

Layfield completed an independent dynamic puncture test with the Enviro Liner® geomembrane for heap leach applications. The Dynamic Puncture test replicates the high pressure in heap leach and waste rock pads using a steel vessel and a hydraulic press. The vessel can apply vertical pressures of up to 4,000kpa, replicating the equivalent of a 200m pile. The EL6040 geomembrane showed no signs of stress or yielding up to 2100kpa, the equivalent of a 120m tall waste rock pile which was less than the proposed height of the waste rock pile.

Following an in-depth evaluation by the engineer, the Enviroliner EL6240, double-side textured, was specified, tendered, and delivered to the project site. Shortly after the delivery of Enviro Liner® material, the project was put on hold, and the material remained on-site and untouched until 2021. During the summer of 2021, the owner resumed the project; however, before allowing the liner installation, the owner wanted the material tested to ensure it was not damaged during the six-year storage period on site.

A sample from each roll was shipped to an independent lab to test physical properties, including mass, elongation, tensile and HPOIT testing. The results for all roll samples still exceeded all current specifications, and the material was approved for installation.

Installation

Layfield installation crews worked closely with the mine owner-contractor to install the geomembrane according to the Layfield Geomembrane Installation and Quality Assurance program over a 2-week period during the summer of 2021. An increased backfill layer was specified and placed to prevent impact or damage to the geomembrane from wheel loads in areas of roads exposed to rock truck traffic.

Results

The installation of the Enviro Liner EL6240 across the waste rock pad was completed on time and successfully. The project team was pleased with the overall installation of the system.