The Layfield Geosynthetics team was out in full force at this year’s Geosynthetics Conference 2023 in Kansas City, Missouri. Brian Fraser, MBA, Vice President – Strategic Business Development Geosynthetics; Rohit Sati, M.Sc., MBA, Technical Product Manager Geosynthetics Canada; and Alex Gersch, Business Development Manager Geosynthetics Australia, were all chosen as industry experts to present multiple technical papers highlighting Geosynthetics and their applications. Below you will find a quick summary of each topic and a link to download the full Technical Paper.

Best Practices for the Design and Installation of Geosynthetics Floating Covers

Presented by Brian Fraser, MBA and Douglas Hilts, P.E. (Hilts Consulting Group)

As a result of a growing scarcity of freshwater around the world, reservoirs with geosynthetic floating covers are increasingly being used to retain, store, treat, protect, and distribute large volumes of water. This paper addresses the current best practices in designing and constructing geosynthetic floating covers for municipal potable water and wastewater treatment and storage. This includes important floating cover design requirements for proper floating cover tensioning, buoyancy, ballasting, wind-loads, geometry and the requirements of sumps, troughs, surface water removal and air venting systems requirements. The paper also addresses the lifecycle cost comparisons, economics and sustainability of floating covers as compared to other common structural methods of storing water, including above ground tanks and underground concrete reservoirs. Finally, the paper addresses important material selection, testing, and maintenance requirements that help ensure longer-term performance of bottom liner system geomembranes and floating cover materials exposed to chemical disinfectants, UV light, weather, and other material application stresses related to the day-to-day operation of the floating cover.

View the Full Technical Paper Here

Case Study, Lake Forest Reservoir Relining and Floating Cover

Presented by Brian Fraser, MBA and Douglas Hilts, P.E. (Hilts Consulting Group), and Robert Emmons (Layfield Geosynthetics USA)

This paper highlights a very challenging geosynthetic floating cover project for the Seattle Public Utilities Forest Park Reservoir. The reservoir was first built in 1962 as an open top concrete lined 60-million-gallon containment facility for potable water storage. The reservoir perimeter has a vertical concrete parapet wall with a 2:1 interior reservoir side slope. In 2002, the owner constructed a 28-foot high (8.5 meter) vertical divider wall partitioning the reservoir into two operating cells. The existing geomembrane liner and floating cover material installed in 2002 were showing signs of aging and degradation and required replacement. The new geomembrane liner required a watertight mechanical attachment at the bottom of the parapet wall and extended to the top of the divider wall. The floating cover was anchored mechanically to the top of the perimeter parapet wall and divider wall. The vertical divider wall created specific design and installation challenges for the replacement floating cover and liner. This paper highlights the design challenges and the custom prefabrication and installation techniques needed for the geosynthetic liner and floating cover. In addition, a custom fabricated double trough system was designed and installed to handle the tensioning loads of the floating cover resulting from vertical divider wall. The paper also addresses the importance of the material selection process and the challenges for geosynthetic materials used in floating cover applications resulting from multiple factors, including chemical disinfectants, UV exposure, and the need for material flexibility and folds.

View the Full Technical Paper Here

Lining a Highly Irregular Vertical Wall with Polyruea

Presented By Dave Martin, P. Eng. (Quantum Technical Services Ltd) and Rohit Sati, M.Sc., MBA

Vertical walls for a fire water containment pond were cut into bedrock and covered with shotcrete. The shotcrete was anchored into the bedrock at roughly 1m intervals. This created a highly uneven surface both on the macro level (with large bulges in the shotcrete at the anchor points), and at the micro level (with smaller dimples in the surface. A conductive geotextile was hung down the vertical walls, and anchored in place with mechanical connections. A spray applied fast set polyurea was applied over the geotextile to create a composite liner. Once filled the pond was over 9 m deep and the water pressure forced the liner to completely conform to the convoluted shape of the wall. The polyurea/geotextile composite liner was able to stretch over and into both the large scale and small scale irregularities in the subgrade. The conductive geotextile allowed spark testing of the composite liner before the pond was filled and after initial filling when the pond was drained. Spark testing was able to demonstrate that the composite liner provided an effective water barrier in this application.

View the Full Technical Paper Here

Development of a conductive textile and its uses in electrical leak location (ELL) survey of geosynthetic containment systems

Presented By Rohit Sati, M.Sc., MBA

Electric Leak Location (ELL) surveys have proven to be a reliable method to evaluate construction integrity of containment systems. The challenge often encountered with this method is providing a consistent conductive layer beneath the geomembrane to facilitate an effective survey. Factors affecting a consistent conductive layer include: a non-conductive subgrade, inconsistent seams with conductive sheet, multi-layer containment systems with non-conductive intermediate layers, spray applied liners and several others. This paper details the development and testing of a unique conductive composite of nonwoven geotextile and a thin conductive film to overcome these issues by providing a consistent conductive layer that can be used under any non-conductive sheet, or between geomembranes where drainage layers may be present. Multiple scenarios replicating the cases noted above were simulated and tested and are featured in this paper. The author found that testing sensitivity of the exposed/bare ELL methods was extremely reliable when using the new material, and the equipment could find holes less than 1mm in diameter. Testing sensitivity was proven to be effective, and holes were successfully detected at applied test voltage between 15-35 kV.

View the Full Technical Paper Here

Emerging Uses of Geosynthetic Floating Covers in the Energy Sector

Presented by Alex Gersch

There are emerging applications in the energy sector, adapting geosynthetic floating cover technology for various renewable energy processes, including generation, storage and saving functions. Climate change has seen a significant focus on renewable energy generation and storage, carbon emission reduction, conserving water resources, and reducing the environmental impact of the energy industry. Water utilities have significant experience with floating covers in reducing the energy required in water treatment and to capture biogas at wastewater treatment plants. Utilities are now combing floating cover and photovoltaic solar power knowledge to transition to become energy generators rather than energy consumers. Large scale energy storage applications are now emerging using heated and chilled liquid storages, with insulated floating covers. This thermal energy is being used to generate electricity through an Organic Rankin Cycle engine or to provide direct heating. Trends are also changing in the oil and gas industry and floating covers are increasingly being used by the industry to reduce energy consumption and to protect water and the environment. This paper discusses the current applications, current developments, and future trends.

View the Full Technical Paper Here

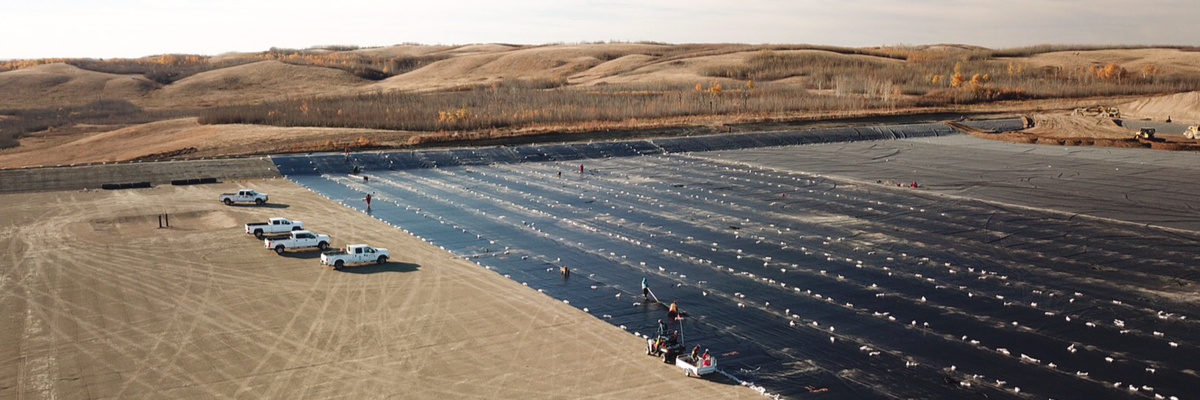

High Performance Geomembranes in Aggressive Mining Applications

Presented by Alex Gersch

Operating conditions associated with mining activities can generally be classified as aggressive environments. Liquor retention ponds, evaporation ponds and tailings dams are some of the mining applications which require geosynthetic liners with specific mechanical and chemical compatibility properties, which are usually the focus of owners and designers when assessing suitable geomembrane materials. Previous project specifications have often been adopted without consideration of the lessons learnt in previous long term mining applications. Additionally, the impact of environmental ambient conditions can be overlooked or given second order priority during the assessment process. This paper discusses the approach taken by an Australian project team to select a suitable geomembrane material for use in a critical evaporation pond application containing a very acidic liquor with very high UV exposure combined with very high maximum ambient temperatures exceeding 40 deg C. The project team underwent an extensive testing protocol to better determine how a combination of factors influenced the material assessment process and final material selection.

View the Full Technical Paper Here

Related Articles

View All News