Improve The Lifetime Performance Of Your Road

High-strength geotextiles extend the expected life of your roads by preventing the mixing of fill and subsoil and reducing the amount of fill required.

Specially designed for base course reinforcement and subgrade stabilization for roadways and similar applications, high-strength geotextiles are woven from high-tenacity polypropylene or polyester fibers (or a blend of both). Layfield offers the most innovative and technology-enhanced wovens on the market, including Tencate’s H2Ri and Rsi for the most demanding applications.

Why Choose A High-Strength Geotextile?

Reinforcement Strength

Higher tensile properties per ASTM D4595 than any other comparable stabilization product.

Durability

Excellent damage resistance for moderate to severe stress installations, making them an ideal solution for long-term reinforcement.

Improved Soil Interaction

Good soil confinement resulting in even load distribution.

Mirafi® H2Ri

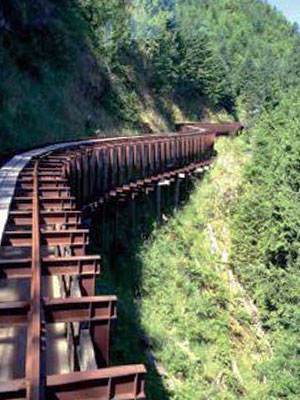

A revolutionary continuous moisture management system for base course reinforcement and subgrade stabilization of Transportation, Site Development, and Energy Infrastructure projects such as roads, railways, and airports.

Mirafi® RSi-Series

RSi‘s unique double-layer technology provides high modulus strength and excellent separation with superior filtration and drainage. This means installing one product rather than two to provide the reinforcement and separation/filtration functions with suitable drainage.

Mirafi® HP-Series

HP-Series geotextiles are woven polypropylene products that are designed to provide separation, filtration, and reinforcement for a variety of soil stabilization conditions.

Product Details

High-strength geotextiles prevent the mixing of fill and subsoil, reducing the amount of fill required and extending the expected life of a road.

Downloads

Resources

Explore the resources available to help you acquire additional knowledge on our products. If you cannot find what you are looking for, we are here to help.

Case Studies

Discover a wide range of completed Layfield projects in various applications worldwide.

Webinars

Our Technical Services Team continuously creates and presents webinars and lunch presentations to better educate our clients. We would be happy to provide you and your group with a customized presentation based on your specific needs. We are also pleased to provide a series of pre-recorded webinars curated for this product group and shown below.

New Advances in Base Course Stabilization and Reinforcement

Join Layfield Geosynthetics, Dave Mueller, Technical Product Manager – Soil Reinforcement, and Glenn Eckert, Engineering Business Manager, in understanding and using the most technically advanced geosynthetic materials to speed construction operations and improve the life expectancy of your project.