Welcome to Our Technical Series

This Series is designed to deliver practical, expert-driven insights into the world of geomembranes and geosynthetics. Whether you’re an engineer, project manager, or environmental specialist, this Series will equip you with valuable knowledge and update you on the latest industry advancements.

Beneath the Surface: Solving Waterproofing Challenges with Geomembranes

Protecting Water Quality

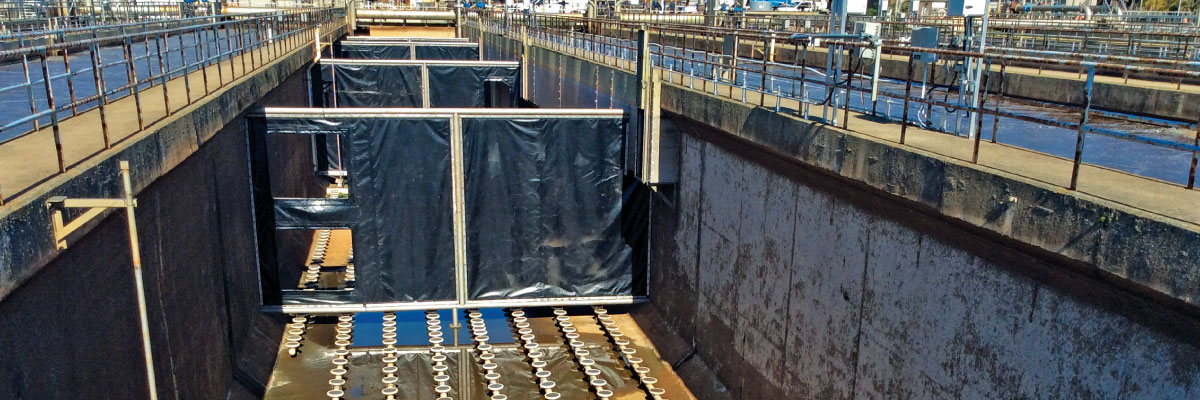

City of Everett, WA, underground concrete potable water reservoir lined with 45 mil CSPE.

City of Everett, WA, underground concrete potable water reservoir lined with 45 mil CSPE.

Geomembranes are playing an increasingly vital role as waterproofing barriers in underground concrete reservoirs and clearwells designed for potable water storage. These underground systems help preserve drinking water quality by shielding it from sunlight and temperature fluctuations that can encourage bacterial growth. They also offer protection from surface contamination and provide added security during emergencies such as power outages or natural disasters.

Challenges with Concrete Reservoirs – Older concrete reservoirs often experience drying shrinkage, which reduces tensile strength and can lead to leakage and cracking. Cracking may also develop due to aging, corrosion, thermal expansion and contraction, hydrostatic pressure, and waterproofing issues.

Installation Challenges – Installing geomembranes in underground reservoirs presents many challenges, including tight space constraints, limited access, vertical columns, inlet and outlet pipes, stairwells, structures, poor lighting, and ventilation. The installation process requires rigorous and careful mechanical anchorage of the liner using stainless steel bars, neoprene gaskets, and anchor bolts.

Material Selection – Selecting the right geomembrane material for underground reservoirs is crucial. Flexible geomembranes are important to accommodate angles, folds, and bends, and allow for custom factory-fabricated panels, minimizing field welds. The geomembrane must also have suitable chemical resistance to disinfectants, including chlorine and chloramine, which can cause stress cracking and premature degradation of the geomembrane.

Layfield’s Solution – For long-term containment of potable water in underground concrete reservoirs, Layfield recommends HypaFlex® CSPE, a reinforced synthetic rubber geomembrane with a proven performance history of over 50 years. Engineered for durability and reliability, HypaFlex® CSPE offers:

- Superior chemical resistance to disinfectants such as chlorine and chloramine

- NSF/ANSI 61 certification to be used in direct contact with drinking water.

- Geomembrane Flexibility to conform to complex reservoir shapes.

- Withstand harsh environmental conditions, including high ambient heat and cold temperatures.

This makes it an ideal solution for potable water reservoirs, pond liners, and floating covers.

For more information on our products, or to learn more about Layfield’s highly skilled construction crews with experience in executing complex geomembrane installations in underground water reservoirs. Ask an Expert!

Written by Brian Fraser, Layfield Geosynthetics

Related Articles

View All News