Written by Andrew Mills | Layfield Geosynthetics

HypaFlex™ CSPE, also known as Hypalon, has been used as a floating cover and roofing material for over 40 years. One of the key features of HypaFlex™ CSPE is the ability to make repairs throughout the life of the material. Following proper procedures, repairs can be made with HypaFlex™ CSPE liners and floating covers in use for over 30 years.

The polymer used to make HypaFlex™ CSPE (Chlorosulphonated polyethylene) is a rubber. When manufactured, the polymer is a thermoplastic but then cures over time to create a thermoset type of rubber. Most rubbers are cured during manufacture, but HypaFlex™ CSPE is made so that it doesn’t cure immediately. This thermoplastic stage allows us to weld the HypaFlex™ CSPE together during fabrication and installation. Then, the polymer cures, making the material more flexible, stronger, UV resistant, and chemically resistant.

The curing of HypaFlex™ CSPE starts on the surface and works its way into the interior. When repairing HypaFlex™ CSPE that has been installed for a short period of time (up to 5 years), it may be possible to re-activate the surface so that welding can take place. Wiping the surface with a solvent such as xylene can often re-activate the surface for welding. Your installer can do a test to determine if the surface can be re-activated.

But, the key attribute of HypaFlex™ CSPE repair is its ability to be adhesively bonded. Rubbers are regularly adhesively bonded, and the joints produced are reliable and durable. Adhesive bonding of HypaFlex™ CSPE can be done at any time during its service life, and the adhesive repairs will last for the life of the substrate.

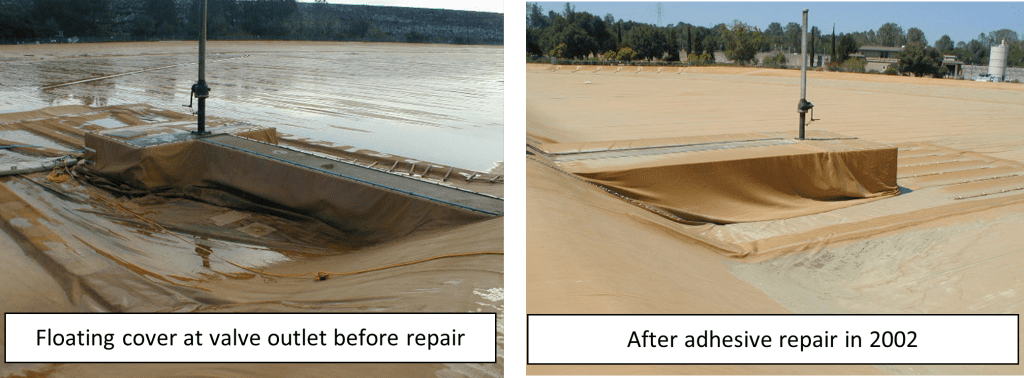

An excellent example of repair of an aged HypaFlex™ CSPE floating cover is the Hinkle Reservoir in Folsom, California. The HypaFlex™ CSPE (Hypalon) floating cover was installed in 1979 and is still in service 40 years later. In 2002, a section of the cover around an outlet valve was replaced. That repair was done on 23-year-old material and has held up perfectly for the past 17 years. Additional minor repairs were completed at the 37-year life of the material, with the material continuing to perform well.

Related Articles

View All News