PROJECT SUMMARY

The Layfield technical team collaborated with both engineering firms appointed by NAV Canada to serve as the owner’s engineer and design engineer for a unique site application. The project involved managing a PFOS-contaminated soil pile located next to an airport strip in Victoria, BC, which presented several engineering and environmental challenges. To mitigate contamination risks, the engineering team was tasked with covering the pile using a chemical-resistant membrane. However, due to the site’s visibility and location, NAV Canada requested a green facia to maintain aesthetic standards.

SOLUTION

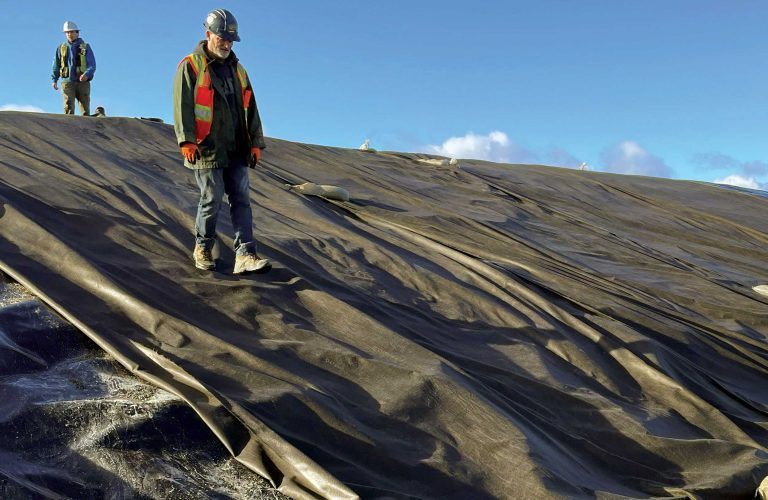

The Layfield technical team developed a preliminary containment solution known as the “Burrito Wrap” design, tailored to meet the site’s unique environmental and structural requirements. This multi-layered system included the following components:

- LP8 Geotextile – Provided separation and filtration as a protective layer.

- Enviro Liner® 6040 Geomembrane – Chosen for its exceptional chemical resistance, particularly against PFOS compounds. Designed for a lifespan exceeding 25 years, it ensures long-term containment performance.

- GEOWEB® Cellular Confinement System with Tendons – Engineered to stabilize vegetation on steep slopes, supporting root growth while preserving slope integrity without compromising the membrane.

- HydraNet® Geocomposite – Served dual functions: facilitating drainage of surface and subsurface water, and reducing the need for imported clean sand, thereby optimizing material usage and installation efficiency.

Layfield’s sales and construction teams provided end-to-end support throughout the project, including material supply, logistics coordination, and on-site installation—ensuring seamless execution and full adherence to design specifications.

CHALLENGES & RESULTS

A key challenge in the project was sustaining vegetation on steep slopes—some with gradients as steep as 1:1—without compromising the integrity of the protective membrane. Traditional anchoring methods, such as soil nails or mechanical fasteners, were not viable, prompting the need for innovative solutions that could secure vegetation without puncturing the membrane. This approach helped prevent moisture ingress and maintained environmental safety.

The total volume of the contaminated soil pile was 3,435 m³. By minimizing the need for extensive trucking to remove materials from the site, the project significantly reduced its environmental impact. The system’s streamlined design also delivered cost savings to the contractor by simplifying installation, reducing manpower requirements, and minimizing errors and rework. By avoiding membrane punctures, the system eliminated the need for invasive anchoring methods and heavy machinery—preserving the site’s natural conditions and lowering the carbon footprint during construction.