This Series is designed to deliver practical, expert-driven insights into the world of geomembranes and geosynthetics. Whether you’re an engineer, project manager, or environmental specialist, this Series will equip you with valuable knowledge and update you on the latest industry advancements.

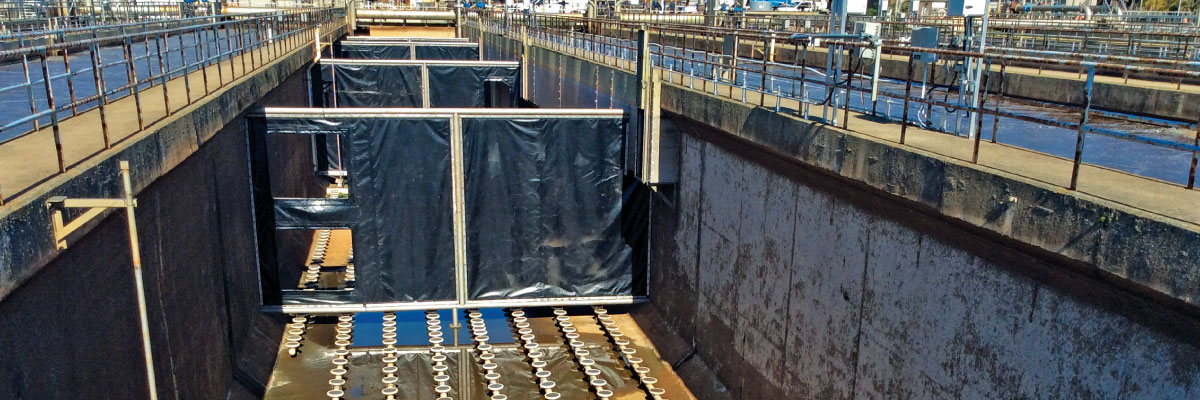

Flow Smarter: How Baffle Curtains Boost Water Treatment Efficiency

Protecting Water Quality

Written by Brian Fraser, Layfield Geosynthetics

Geomembrane-produced baffle curtains are widely used in municipal and industrial water treatment systems. Their chemical resistance, high tensile strength, and durability make them ideal for controlling flow and improving treatment performance in potable water storage, wastewater lagoons, and industrial process water systems.

By increasing hydraulic retention time and minimizing short-circuiting, these baffle curtains contribute to better water quality and more efficient operations.

How Baffle Curtains Work

Baffle curtains guide water through a longer, controlled path between inlet and outlet points, increasing contact time with disinfectants like chlorine—essential for effective pathogen removal.

Benefits

- Increased Hydraulic Retention Time (HRT): Longer water residence improves treatment.

- Improved Efficiency: Reduces BOD, COD, and TSS.

- Eliminates Dead Zones & Short-Circuiting: Ensures complete treatment.

- Cost-Effective: Avoids expensive infrastructure upgrades.

- Flexible & Retrofit-Friendly: Easily integrated into existing systems.

Typical installation sites:

- Clearwells

- Above-/below-ground reservoirs

- Equalization basins

- Chlorine contact chambers

Common Applications

- Wastewater Treatment: Enhances biological processes in lagoons and ponds.

- Drinking Water Treatment: Increases chlorine contact time in reservoirs and clearwells.

- Industrial Water Treatment: Used in sectors like energy, agriculture, and food processing to improve water and wastewater quality.

Types of Baffle Curtains

Fixed Baffles:

Permanently anchored vertical barriers made from impermeable geomembranes are mechanically fastened using stainless steel bars and neoprene gaskets for the tank floors and ceilings.

Floating Baffles:

Suspended barriers with foam top floats for buoyancy and positioning, incorporating weighted chain skirts for ballasting. Floating baffles are commonly used for open concrete treatment reservoirs, earth ponds, and lagoons.

Geomembrane Baffle Materials

Baffle curtains are custom factory-made using flexible, reinforced geomembranes joined by thermal wedge or hot air welding. It is important that materials provide adequate strength, flexibility, and chemical resistance including chlorine. For outside, exposed applications, the material needs to be highly UV stabilized and have good high and cold temperature resistance. For potable water use, they must meet NSF/ANSI 61 or equivalent standards.

Typical custom fabrication features include reinforced perimeter edges, chain-weighted bottoms, attached steel cables, and flow windows. Floating baffles, including encapsulated polyethylene foam floats for buoyancy and positioning.

Common Geomembrane Baffle materials:

- PVC EIA – PVC + KEE – Reinforced: 30, 36, 45 mil (0.76, 0.91, 1.14 mm)

- CSPE – (former Hypalon): Reinforced 36, 45, 60 mil (0.91, 1.14, 1.52 mm)

- RPE: Reinforced Polyethylene – 30, 36, 45 mil (0.76, 0.91–1.14 mm)

Layfield Geosynthetics is a highly experienced supplier of baffle curtains and provides custom fabrication and installation services.

For more information on our products, or to learn more about Layfield’s highly skilled construction crews with experience in executing complex geomembrane installations in underground water reservoirs. Ask an Expert!

Related Articles

View All News