This Series is designed to deliver practical, expert-driven insights into the world of geomembranes and geosynthetics. Whether you’re an engineer, project manager, or environmental specialist, this Series will equip you with valuable knowledge and update you on the latest industry advancements.

From Flowback to Sustainability: Geomembranes for Produced Water Driving Change in Upstream Oil & Gas

Protecting Water Quality

Written by Brian Fraser, Layfield Geosynthetics

Hydraulic fracturing has unlocked vast energy reserves—but it also creates a critical challenge: managing the millions of gallons of water that return to the surface. As operations expand, the use of geomembranes for produced water containment is growing rapidly. Safe management isn’t optional—it’s essential for protecting the environment and ensuring operational efficiency.

Produced Water Overview

During hydraulic fracturing, millions of gallons of water are injected at high pressure through the wellhead into underground formations to release hydrocarbons. Flowback refers to the fluid that returns to the surface after fracturing is complete. This fluid, categorized as produced water, is a complex mixture that typically includes:

- Salts and brine

- Hydrocarbons (oil and grease)

- Suspended solids

- Heavy metals

- Chemical additives used in drilling and stimulation

The composition of produced water varies significantly based on reservoir geology, well design, and extraction method. Flowback fluids returning to the surface are typically at elevated temperatures, ranging from 100°F to 200°F (38°C to 93°C). Once separated and stored, produced water in surface containment ponds and tanks generally cool to ambient conditions, but may still retain residual heat, dissolved solids, hydrocarbons, and treatment chemicals.

Produced water is increasingly recycled for hydraulic fracturing, driven by environmental and cost-efficiency goals. While deep well injection remains common, treatment and reuse are gaining traction to reduce freshwater demand and disposal volumes.

Environmental Compliance & Containment Design

Produced water is usually classified as a critical containment due to its potential environmental impact. Regulatory requirements differ by location, but most regions mandate robust containment systems, which typically include:

-

- Double-lined geomembrane with geocomposite drainage layer

- Electrical leak detection and leak monitoring

- CQA destructive and non-destructive testing protocols during installation

Storage Solutions & Material Selection

Produced water is commonly stored in two types of containment systems:

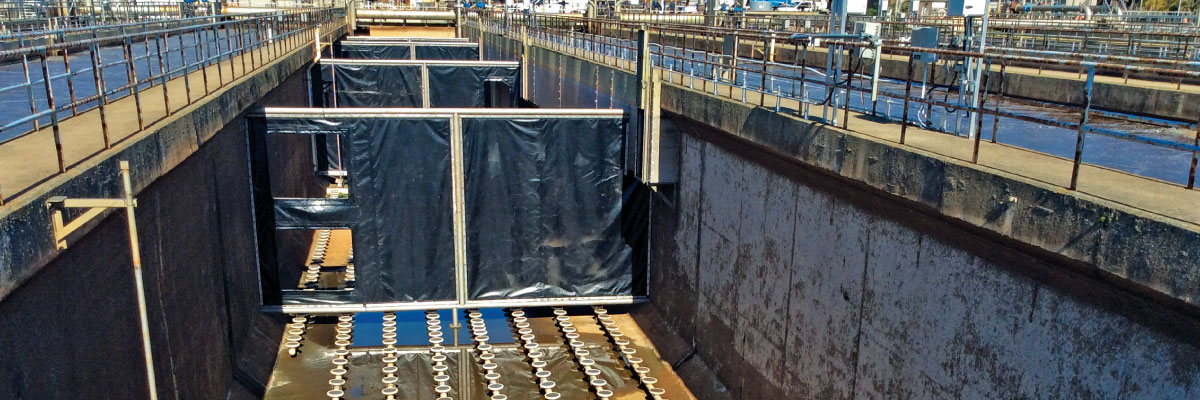

- Earth-lined ponds – Typically lined with HDPE geomembranes, valued for chemical resistance and durability.

Above-ground steel tanks – Often lined with LLDPE liners, offering flexibility and conformability to tank geometry.

In demanding and environmentally sensitive applications, Enviro Liner® 6000, a highly stabilized, blended HDPE/LLDPE geomembrane, is often selected to deliver long-term performance tailored to specific site conditions. For produced water ponds and tanks, geomembrane liners are typically exposed rather than backfilled, a factor that significantly influences material choice for a highly UV-stabilized and chemically resistant material.

In environmentally sensitive regions, multi-layer geomembrane systems are emerging, incorporating up to three layers of geomembrane, geonet composites, and heavy non-woven geotextiles.

Service Life Expectations

- Short-term installations (e.g., mobile or temporary tanks): 3 months to 10 years

- Long-term centralized water hubs supporting major shale plays up to 20 years

Layfield’s Expertise

At Layfield, we go beyond supplying liners—we deliver engineered containment solutions tailored for the toughest upstream oil and gas challenges, including:

- HDPE and LLDPE – GRI GM13 & GM17 Grade

- Enviro Liner® 6000 – Blended geomembranes for extended performance

- Geovolt® – Conductive geotextile for electrical leak detection

- HydraNet® – Geocomposite drainage products for enhanced system performance

As a vertically integrated provider, Layfield delivers manufacturing, fabrication, and installation services to ensure prompt service, quality, and reliability. As hydraulic fracturing expands globally, multi-layer geomembrane containment systems remain crucial for striking a balance between operational efficiency and environmental protection.

For more information on our products, or to learn more about Layfield’s highly skilled construction crews with experience in executing complex geomembrane installations in underground water reservoirs. Ask an Expert!

Related Articles

View All News

Above-ground steel tanks – Often lined with LLDPE liners, offering flexibility and conformability to tank geometry.

Above-ground steel tanks – Often lined with LLDPE liners, offering flexibility and conformability to tank geometry.