From Drilling Fluids to Hazardous Waste Containment, We Have You Covered

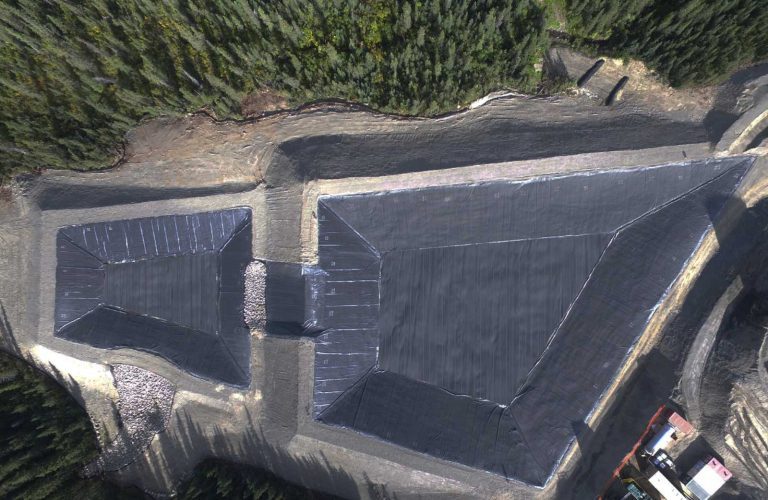

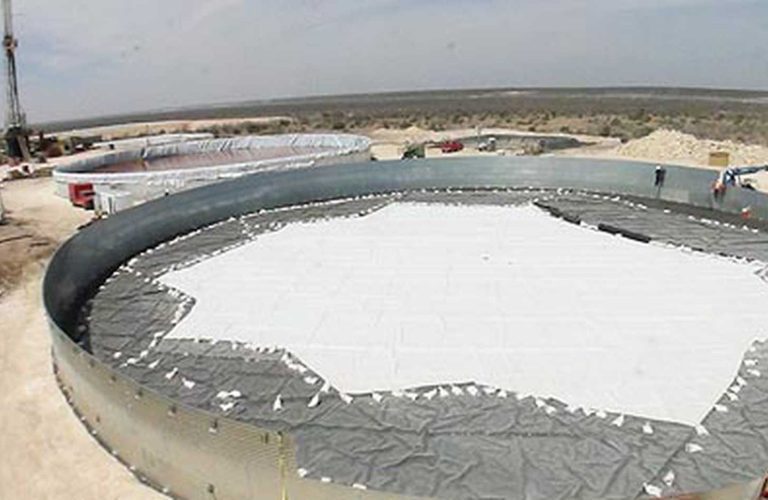

With its exceptional flexibility and endurance properties, Layfield’s Enviro Liner® (EL) brand of geomembranes has been a trusted performer in our portfolio for many years. Available in four unique formulations, this series of geomembranes offers solutions for a wide range of containment applications.

The flagship Enviro Liner® 6000 incorporates the latest ultraviolet/anti-oxidant (UV/AO) stabilization technology, providing a new level of UV resistance and endurance properties. It is designed for long-term exposed applications and has excellent chemical resistance, making it one of the most durable geomembranes on the market.

Why Choose the Enviro Liner® Brand of Geomembranes?

Excellent Interface Friction Properties

EL1000, EL4000, and EL6000 are available in textured versions on one or both sides, providing superior friction properties.

Reduced Installation Costs

Enviro Liner® is a flexible membrane liner that can be factory fabricated to deliver to the site as large panels, making for an easier installation.

Offering Green Solutions

We've manufactured our Enviro Liner® 3000 using 100% recycled resin, helping you reach your project's sustainability goals.

Additional Features

- Can be prefabricated into large panels

Enviro Liner® 1000

A flexible membrane liner developed for the containment of drilling fluids and water used in hydraulic fracturing operations.

Enviro Liner® 3000♻

An economical lining material made from blended/reprocessed polyethylene resins selected for optimum performance at the lowest cost.

Enviro Liner® 4000

A specialized LLDPE polyethylene lining material that combines flexibility, UV stability, and chemical resistance, allowing for easy accommodation to differential settlement.

Enviro Liner® 6000

Enviro Liner® 6000 is NSF 61 compliant and fortified with the latest in Ultra Violet/Anti Oxidant (UV/AO) stabilization packages, providing exceptional UV resistance and making it ideal for long-term exposed applications.

Product Details

With its exceptional flexibility, Layfield’s Enviro Liner® (EL) brand of geomembranes offers solutions for a wide range of containment applications.

Downloads

Resources

Explore the resources available to help you acquire additional knowledge on our products. If you cannot find what you are looking for, we are here to help.

Case Studies

Discover a wide range of completed Layfield projects in various applications worldwide.

Webinars

Our Technical Services Team continuously creates and presents webinars and lunch presentations to better educate our clients. We would be happy to provide you and your group with a customized presentation based on your specific needs. We are also pleased to provide a series of pre-recorded webinars curated for this product group and shown below.

Lessons from the Field: Constructing Geomembranes

For over 45 years, Layfield Geosynthetics has offered design support, manufacturing, installation, and servicing a wide range of Geomembranes. During this recorded webinar, we will discuss geomembrane selection, installation, testing concerns, and address the common challenges in selecting a reliable geomembrane installer. Join Glenn Eckert, Engineering Business Manager at Layfield, and Greg Parrent, Construction Business Manager at Layfield, for this comprehensive webinar.

Geomembrane Manufacturing Using Blown Film Process

Join Layfield Geosynthetics Deep Gulati, Technical Services Manager – Extrusion, and Justin Gouthreau, Engineering Business Manager – Group Manager, as they explain how geomembranes are manufactured using several processes like blown film, cast film, and calendaring. This webinar will focus on manufacturing smooth and nitrogen-textured co-extruded geomembranes using blown film process.