Project Summary

The town of Napanee is located in Southeastern Ontario along the shores of Lake Ontario. The A.L Dafoe water treatment plant, which services approximately 8500 properties, draws water from Lake Ontario. The raw water is pumped from the lake and stored in a 450m3 below ground concrete reservoir and a 1300m3 above ground exposed geomembrane lined reservoir.

During the annual inspection, it was determined that the liner in the exposed reservoir had reached the end of its service life and required replacement. Jewel Engineering, working on behalf of the Town of Napanee, reached out to Layfield’s technical services team for advice on replacing the lining system and adding a geomembrane floating cover system to protect the raw water contents inside the reservoir.

They required a long-term, reliable containment system to safely store the town’s raw water supply and survive the harsh Canadian climate. The reservoir’s floating cover would need to protect the lagoon’s contents, manage snow and rain precipitation, and resist UV degradation.

Project Scope and Challenges

Layfield’s Enviro Liner® 6060 was the geomembrane selected for the primary containment lining system. This 60 mil geomembrane is manufactured with prime-grade resins and antioxidants to deliver a long-term, reliable solution. It is also approved for contact with potable water (NSF 61) and has an excellent track record in similar containment applications.

Layfield’s construction team utilized prefabricated geomembrane panels to expedite the installation timeline and attached the liner to the concrete tank edge using an SS316 flat bar and a neoprene gasket. To minimize the chance of leaks, QAQC was essential. To help with efficient electrical leak detection testing, Layfield installed a layer of 6oz Geovolt Conductive Composite on the subgrade prior to the Enviro Liner® geomembrane. Geovolt® provides a uniform conductive subgrade to increase the efficiency of electrical leak surveys while protecting the liner interface.

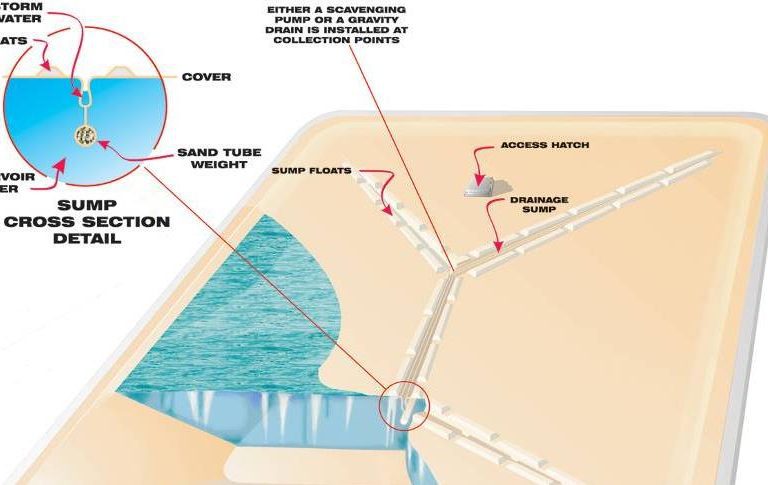

Layfield also designed and installed a HypaFlex™ Chlorosulfonated Polyethylene (CSPE) defined sump floating cover system to protect the exposed raw water. The system is a passive system consisting of a network of rainwater collection trenches that manage precipitation and slack while protecting content from elements and contaminants.

Results

After minor subgrade and concrete repairs, the lining and cover system were installed in less than a week. The owner was pleased to have the facility back up and running and to restore the reservoir’s operating capacity. Due to a tight construction timeline, the prefabricated key system components reduced the on-site installation time. The owner and project team were pleased with the final solution and Layfield’s expertise and attention to detail.

Features & Benefits

Enviro Liner® 6060 geomembrane fortified with the latest in Ultra Violet/Anti Oxidant (UV/AO) stabilization packages, providing exceptional UV resistance and making it ideal for long-term exposed applications. Geovolt® enables effective electric leak detection under almost any geomembrane. HypaFlex™ CSPE is engineered to withstand extreme heat and UV exposure and is backed with an industry-leading 30-year weathering warranty.