PROJECT SUMMARY

The Humber Treatment Plant was originally constructed in 1960 and is Toronto’s second-largest wastewater treatment plant. It services approximately 680,000 residents with an annual capacity of 473,000m3. The facility underwent extensive upgrades to improve air quality and odor issues, including biofilters to clean the emissions from the plants. The biofilter consists of a group of concrete tanks which contain biofilter media. Air collected from various locations and buildings at the plant is pumped into the tanks via a series of ducts and filtered by the media to reduce odor and emissions. A recent inspection at the plant determined that the biofilter media had reached its end of life and required replacement. During the removal of the biofilter media and tank clean-out, it was decided to improve the integrity of the containment and install a geomembrane lining system within the tank as an added level of protection against any leakage that may occur.

MATERIAL SELECTION

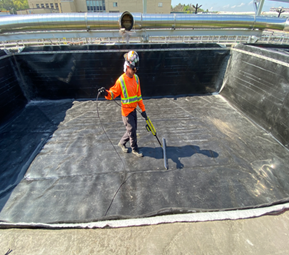

Installing a geomembrane liner in a critical containment application within a square concrete tank with corners is particularly challenging and complex. This geomembrane installation required experienced installers that followed a strict installation protocol and QA/QC program. The contractor working on behalf of the City of Toronto reached out to Layfield for recommendations for a suitable geomembrane to contain the biosolids in an exposed tank application.

Layfield’s installation team conducted a field evaluation and recommended a GeoFlex™ 60mil (1.5mm) polyolefin geomembrane as the most appropriate for the application to line the three 8m x 5m x 1.4m concrete biofilter tanks. The GeoFlex™ prime grade resin and antioxidant formula provide excellent chemical and UV resistance for this application. In addition, the GeoFlex™ has a high degree of flexibility and elongation compared to other 60mil geomembranes to allow more efficient installation within the tank edges, corners, and around penetrations within the tank.

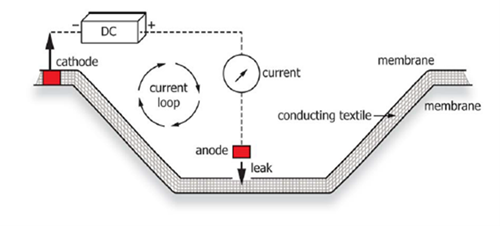

To help ensure there were no leaks in the installed geomembrane, the owner chose to perform an Electric Leak Location Survey (ELLS). This was facilitated with Layfield’s innovative Geovolt® geotextile. The geotextile provided a conductive layer beneath the non-conductive geomembrane, allowing the ELLS to find even the tiniest holes. During the ELLS, the technician places a voltage across the geomembrane and identifies any areas where the current flows through the geomembrane, thus identifying a leak. Once Geovolt® is installed, it gives the owner flexibility to conduct leak surveys again in the future as part of inspection and maintenance programs. As a secondary function, the Geovolt™ provides a protective layer between the geomembrane and the concrete surface.

INSTALLATION

The concrete biofilter tank was lined by the installation team with a continuous layer of Geovolt®. Seams were overlapped to create a continuous conductive surface. Following the installation of the Geovolt®, the GeoFlex™ geomembrane seams and penetrations were fusion welded, and the liner was mechanically attached at the top of the tank using a typical mechanical attachment consisting of an SS316 ¼”x2” bar & gasket. Pipe penetrations within the tank were flush-mounted, which presented another challenge as typical pipe boots to seal the penetrations would not be appropriate as they required an exposed piece of pipe to seal around. To remedy this, the installers created a picture frame attachment to seal the liner around the flush pipe penetration and compression fitted to the tank to create a dependable seal.

After the liner installation was completed, the installation team was able to conduct the electronic leak survey. There are a variety of leak location techniques that can be considered. The Arc Test Method D7953 was chosen for this installation as this method is most appropriate for clean, dry, uncovered geomembranes. During the survey, one electrode is connected to the Geovolt® conductive geotextile below the liner, and a second electrode with high-voltage DC power is introduced above the liner. Where a leak occurs, the circuit is closed, and an arc and auditable tone is created to notify the operator of the leak. Arc testing is a reliable and accurate method that can detect leaks smaller than 1mm in diameter. To validate the testing procedure, the inspector created an artificial leak within the liner to verify the testing equipment would detect it.

Result

The installation teams completed the installation of the Geovolt® and GeoFlex™ in 5 days. The decision to use the flexible GeoFlex™ 60mil saved time on the installation and detail work in the tight corners. The Geovolt® worked as expected, allowing for an efficient and reliable electronic leak inspection. Overall, the site contractor and owner are pleased with the installation. This project provides an excellent example of two recent innovations in geosynthetics working together to deliver a more reliable containment and product for the facility owner.