Project Summary

An impervious parking area at the existing Fortis BC yard in Kelowna, BC, required an additional 920 cubic meters (243,000 gallons) of onsite stormwater storage for infiltration. Due to the limited footprint and high-water table, the only location for the stormwater management system would be under the newly paved parking area. The yard and parking area see regular traffic of Fortis fleet vehicles, but also gets a semi-annual visit from a mobile substation. The substation requires oversized and overweight permits to travel and is moved from location to location by a private contractor. It is 20m long (65’) and has a GVW of 55,120kg (121,000 lbs), which is more than twice the maximum for HS-25 loading. A typical Brentwood system with 610mm (2’) of cover is rated for HS-25 loading (23,000kg / 53,000 lbs), so additional reinforcement and load distribution would be required above the tank for a Brentwood system to be suitable.

Solution

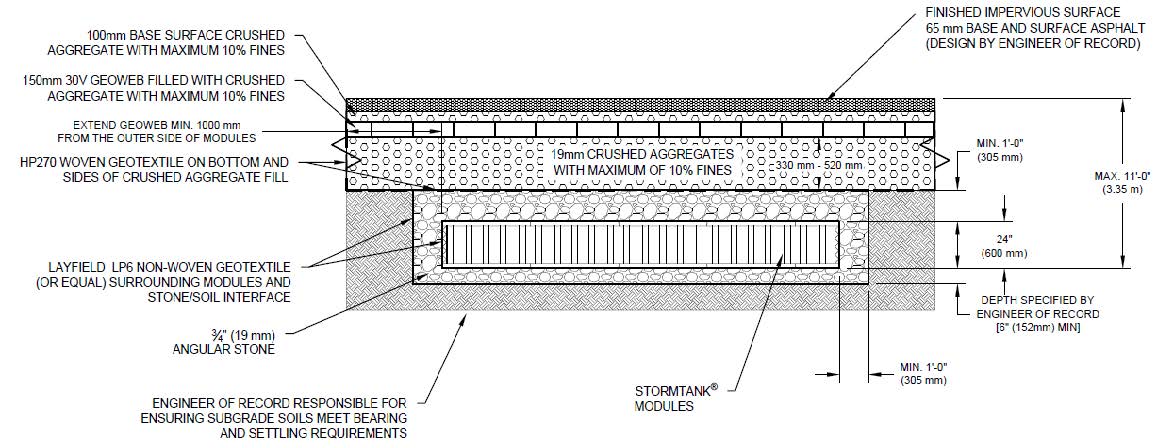

Layfield consulted with Presto Geosystems to devise a solution involving GEOWEB® geocells to reduce vertical pressure above the tank. GW30V6 (6” cell) was selected. The design called for the GEOWEB® panels to extend beyond the footprint of the tank by 1m on all dimensions. Brentwood StormTank® 25 (24” height) modules were used to maximize storage volume within the limited footprint and high-water table. A layer of HP270 high-strength woven geotextile was added for additional reinforcement and separation of stone layers above the tank. Layfield hired a 3rd party engineer (Witzel Dyce) to review and stamp the final design.

Installation

Layfield and Emco Waterworks Kelowna were able to assist R&L Excavating with on-site support during the installation. R&L Excavating has much experience with Brentwood StormTank® installations but has never worked with Presto GEOWEB®. Components for almost 3,500 ST25 modules were shipped directly from Brentwood’s manufacturing in Reading, PA, in 4 containers and then assembled on-site. Separately, 1800 m2 of GEOWEB® (GW30V6-34 cell) and GEOWEB® accessories were shipped from Layfield, along with HP270 woven and LP6 nonwoven geotextile. The project took approximately three weeks to complete, from excavation to final paving.