There When You Need Us for Safe and Reliable Service

Quality installation and routine maintenance lead to superior performance. With over four decades of experience, your company can depend on us to ensure your investment performs over the longterm.

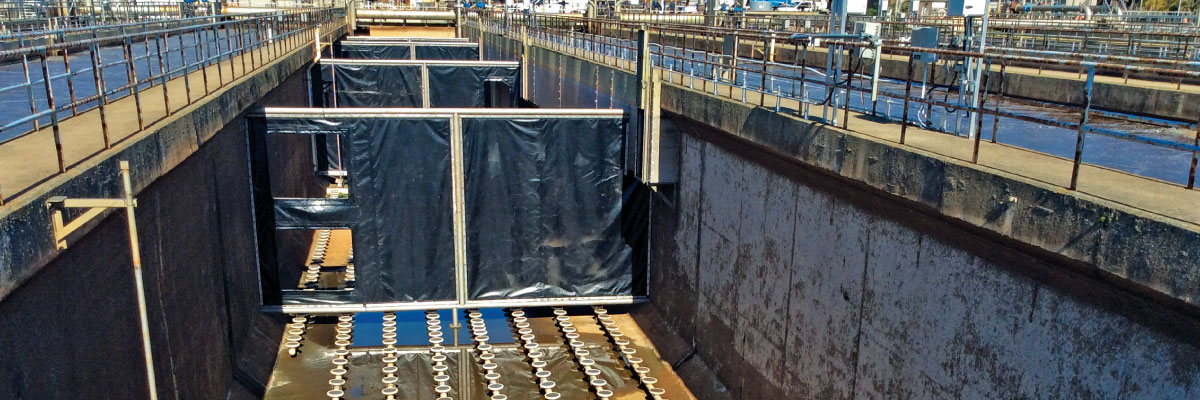

You will benefit from installation crews trained in quality control and safety and with extensive project management experience. We also offer a complete service program specializing in cleaning, inspecting, and repairing geomembranes and floating covers. With us, you will meet your required maintenance regulations and can rest assured every geosynthetic installation is as reliable as the last.

Installation & Maintenance In Action

View All Case StudiesInstallation & Maintenance In The News

View All News